Manufacturer of Finned Tubes, Fin Tube & Finned Pipe

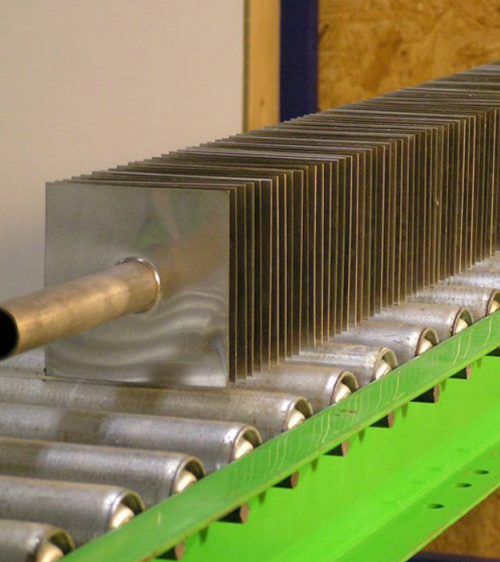

Used in Heat Exchangers, Boiler Economizers, Coolers and Heaters

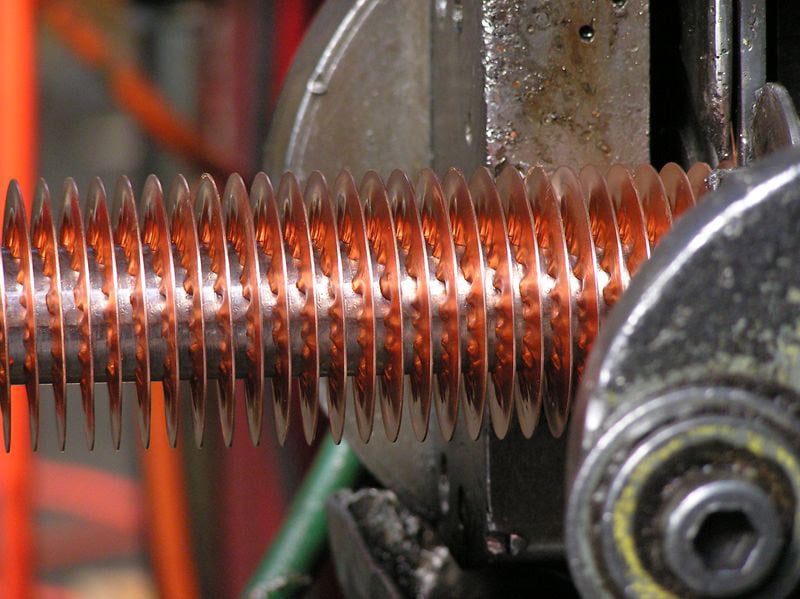

Finbraze®

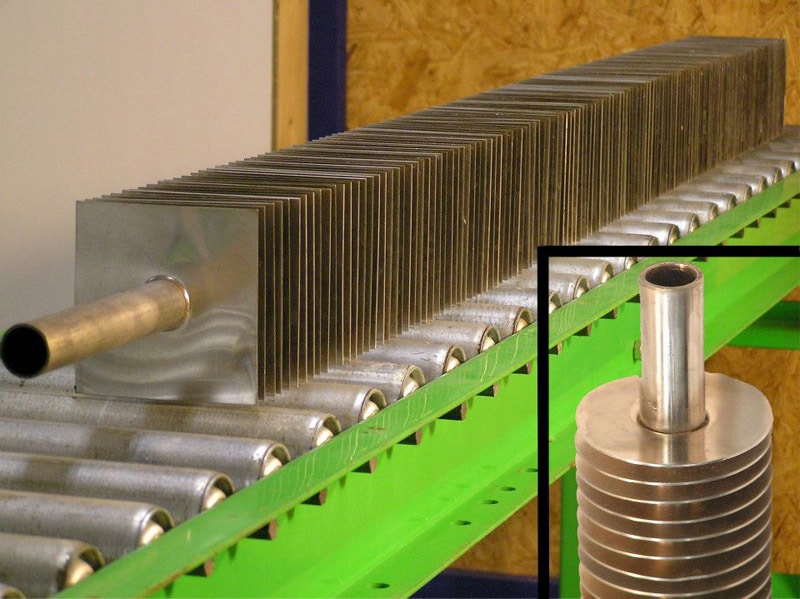

Cladfin®

Mini-Fin

Edge Tension

Stamped/Plate Fin

“L” Foot

Coils and Bending

About Fin Tube Products

Fin Tube Products, Inc. specializes in Helical-Wound Brazed Finned Tubing. We are tooled however, to provide many of the fin to tube attachment methods currently available in today’s market.

Our Finned tubing and finned pipe are used in heat exchangers, boiler economizers, coolers, and heaters. Our small diameter to miniature finned tubes (hypodermic) can be found in cryostats and cryogenic coolers for military use, or in the medical profession for the cryoablation of tumors.

With the use of our in house Atmospheric Brazing Furnace complete control is maintained over the critical brazing process. By avoiding the out sourcing of our brazing your turn around time is improved, and complete quality control is maintained in house.

Fin Tube Products, Inc. offers one of the worlds most diversified finned tubing product lines. Although specializing in a helically wound brazed finned tube, we offer many of the other forms of fin to tube attachments available in today’s market. Our Finbraze® and Cladfin® fin tubes are available in straight lengths, shapes or coils. We offer prototype or production runs. Pricing and delivery is competitive. Our quality is second to none.

Manufacturer of Finned Tubes, Fin Tube & Finned Pipe

Latest News

Understanding the Finned Tube Manufacturing Process

In the world of heat exchange and thermal engineering, finned tubes play a crucial role in enhancing the efficiency of systems used in HVAC, power gen...

Learn MoreUnderstanding Copper Fin Tube Heat Exchangers: Design, Benefits, and Applications

For heat transfer equipment, copper fin tube heat exchangers are recognized for their superior thermal performance, corrosion resistance, and versatil...

Learn More